Mochini o Phatlalatsang oa G-High Speed Layer Co-extrusion Film

| Mohlala | 45/50/55/50/45-1800 | 50/55/65/55/50-2000 | 55/65/75/65/55-2200 | 65/75/85/75/65-2400 |

| Bophara ba filimi | 900-1500 limilimithara | 1000-1800mm | 1200-1800 limilimithara | 1300-2200 limilimithara |

| Botenya ba filimi | 0.03-0.15mm | |||

| Sephetho

| 150-200kg/h | 150-300kg/h | 150-400kg/h | 150-450kg/h |

| Ho ea ka bophara bo fapaneng, botenya ba filimi, boholo ba lefu le litšobotsi tse tala li ka fetoha | ||||

| Lisebelisoa tse so ntlafatsoe | HDPE/LDPE/LLDPE/EVA/MLLDPE | |||

| Diameter ea screw | Φ45/50/55/50/45 | Φ50/55/65/55/50 | Φ55/65/75/65/55 | Φ65/75/85/75/65 |

| L/D karo-karolelano ea screw | 32:1 (Ka ho fepa ka matla) | |||

| Lebokose la gear | 146# *2 180#*1 173# *2 | 173# *2 200#*1 180# *2 | 180# *2 225#*1 200#*2 | 200#*2 250#*1 225#*2 |

| Enjene e ka sehloohong | 15kw*2 30kw*1 18.5kw*2 | 18.5kw*2 37kw*1 30kw*2 | 30kw*2 45kw*1 37kw*2 | 37kw*2 55kw*2 45kw*2 |

| Die bophara | 300mm 400mm | 400mm 450mm | 450 limilimithara 500 limilimithara | 500 limilimithara 550 limilimithara |

Ka holimo ho li-parameter feela bakeng sa litšupiso, e ka etsoa ho latela litlhoko tsa bareki, lintlha tse qaqileng pls hlahloba ntho ea sebele

Tlhaloso ea Sehlahisoa

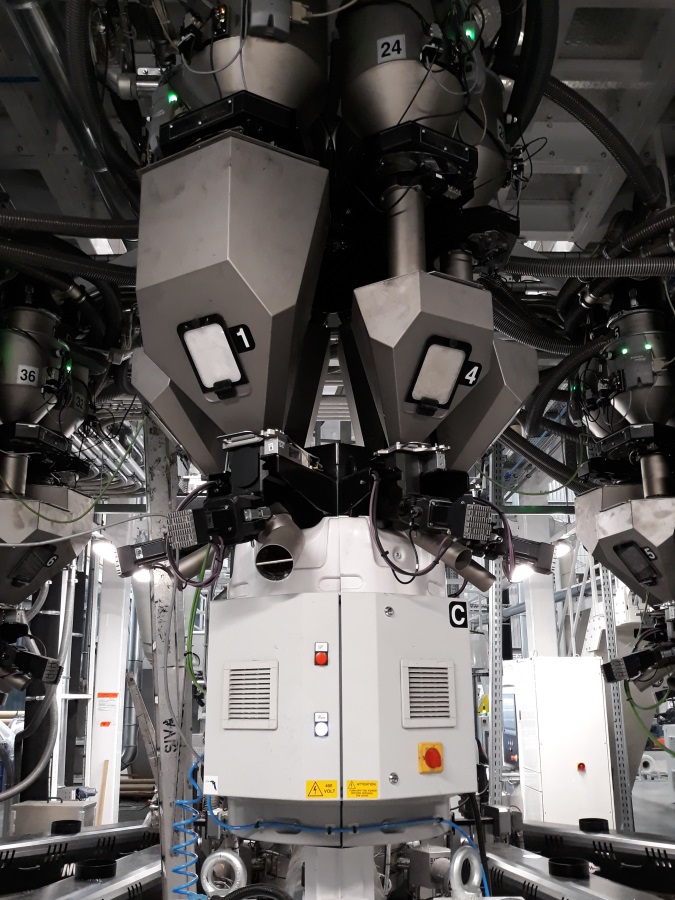

Mochini o fokang lifilimi oa 5 layers o etselitsoe ho khotsofatsa litlhoko tsa hau bakeng sa ts'ebetso e ntle ea ho foka lifilimi liindastering tse fapaneng tse kang lijo le lino, meriana le liphutheloana tsa litlolo.Mochine ona o na le likarolo tse hlano tsa polymer, e 'ngoe le e' ngoe e etselitsoe ho fana ka thepa e ikhethang ho ntlafatsa boleng ba filimi.Mochine oa rona o fana ka mefuta e mengata ea melemo, ho kenyelletsa ho laola mocheso ka mokhoa o itekanetseng, mokhoa o nepahetseng oa tsamaiso ea microcomputer, le mokhoa o ka tšeptjoang oa ho pholisa.

Likarolo tsena li fana ka ts'ebetso e nepahetseng ea mochini le tšebeliso e fokotsehileng ea matla, e etsa hore e be tharollo e bonolo ea tikoloho le e baballang chelete e ngata.Molemo o ka sehloohong oa mochine ona ke ho hlahisa lifilimi tsa boleng bo phahameng ba sekhomaretsi.Ho feta moo, lifilimi tsa boleng bo phahameng tse hlahisoang ke mochine oa rona li ipaka e le khetho e babatsehang bakeng sa merero ea marang-rang le ea papatso.Likarolo tse sebelisoang habonolo tsa mochini oa rona o fehlang lifilimi tse 5 li etsa hore ho be bonolo ho sebetsa le ho ikamahanya le litlhoko tsa hau.Mochini o tla o na le alamo e ikemetseng e lemosang basebelisi ka litlhoko tsa tlhokomelo le ho fokotsa nako ea ho theoha.

Sehlopha sa rona sa boenjiniere se boetse se qapile mochini hore o tšoarelle haholo, o netefatse hore nako e telele ea tlhahiso le litšenyehelo tse tlase tsa tokiso.Mochini oa rona o fokang lifilimi oa mekhahlelo e 5 o na le lits'ebetso tse fapaneng, ho kenyelletsa le lifilimi tsa bophara bo fapaneng, botenya, le mebala eo u ka e khethang.E fana ka mefuta e mengata ea tlhahiso, e u lumellang ho khotsofatsa litlhoko tse ikhethang tsa bareki ba hau.Ts'ebetso ea ho kenya mochini oa rona e otlolohile, 'me sehlopha sa rona se fana ka libuka tsa litaelo tse hlakileng le tse hlakileng mabapi le mokhoa oa ho theha le ho sebetsa mochini.Lintlha tsohle li hlokomeloa ho netefatsa hore o fumana liphetho tse nepahetseng ho tsoa mochining.

Qetellong, mochini oa rona o fehlang lifilimi oa 5 layers ke tharollo e sebetsang, e sebetsang, le e tšepahalang ho fihlela litlhoko tsa hau tsa indasteri.Re motlotlo ka ho fana ka lihlahisoa le lits'ebeletso tse ikhethang tse fihlelang litlhoko tse ikhethileng tsa bareki ba rona, ho netefatsa tlhahiso, phaello le katleho indastering ea hau.

Pontšo ea Sehlahisoa

Sesebelisoa sa boikhethelo:

Automatic Hopper Loader

Filimi Surface Treater

Rotary Die

Yuniti e Oscillating ea Take Up

Liteishene tse peli tsa Surface Winder

Chiller

Mocheso Slitting Sesebelisoa

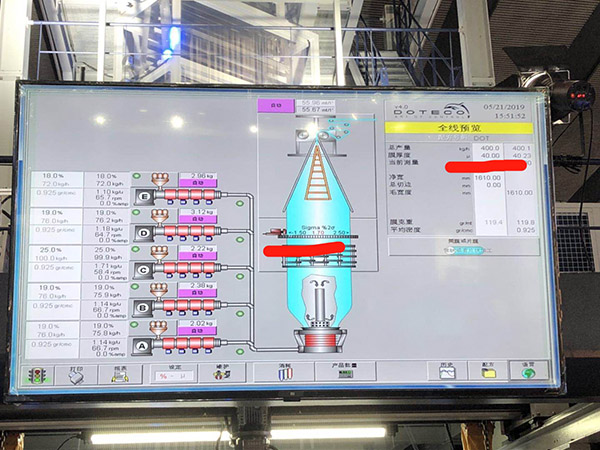

Yuniti ea Tekanyetso ea Gravimetric

IBC

EPC(Edge Position Control)

Taolo ea Khatello ea Elektronike

Sefetoleli sa skrine sa mechanics ka letsoho

Mochini o hlabollang lintho tse bonahalang